Fluoropolymer films

Fluoropolymer films are state of the art materials providing to parts or production processes outstanding chemical resistance, transparency, weather resistance, heat resistance, electrical characteristics amongst others. They are the best solution for a growing number of industries such as electronic, machine, automotive and semiconductors.

DESCRIPTION

Benefits of fluoropolymer films

Daikin has developed a range of films and sheets based on the fluorine technology to meet the growing demand for high-performance films. They allow their users to benefit from the outstanding fluoropolymer's inherent properties.

Product lines of NEOFLON film

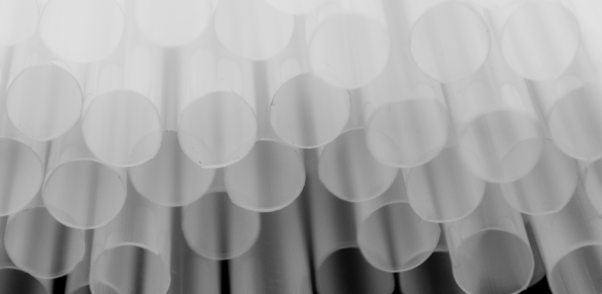

- NEOFLON PFA film: having superior chemical resistance and thermal stability

- NEOFLON FEP film: offering excellent heat resistance, non-stick and electrical performance

Features

- low coefficient of friction

- chemical resistance

- optical transparency

- weather and UV resistance

- heat resistance

- non-flammable

- dielectric properties

Applications

The range of NEOFLON films are suitable for use in a wide variety of applications such as anti-corrosive linings, composite part mold release, industrial roll covers, circuitry, pharmaceutical cap liners, sterile packaging, cable insulation, hot melt adhesive, microphone electret membranes, anti-graffiti coverings, erasable surface, coverings, automotive airbag systems, fuel hose permeation barrier, hot melt adhesive and more.

NEOFLON films adapt to conventional processes and secondary operations such as heat seal, thermoforming, welding, and heat- bonding, lamination, die-stamp. Each of the film grades is available in various, size, weight and thicknesses to meet the most specific requirements.

- Semiconductors manufacturing equipment require chemical-resistant liners for etching bath, restraining process downtime

- Construction and infrastructure segment players are continuously seeking for sustainable solutions such as water-repellent architectural fabrics, anti-graffiti coverings, protection against extreme corrosion, fading or cracking

GRADES & FEATURES

Types and features of fluoropolymer films

| Type | Main applications / molding method | Features |

|---|---|---|

|

NEOFLON PFA film |

Corrosion resistant lining, aircraft mold release, printed circuit board, electret condenser microphone |

Keep robustness and flexibility over a wide temperature range Excellent in chemical resistance Low-dielectric properties |

|

NEOFLON FEP film |

Excellent heat resistance Chemical resistance Non stickness Incombustibility Electrical properties Low-dielectric properties |

Characteristics of fluoropolymer films

Priority from general material "D" : A>B>C>D

| Type | PFA | FEP |

|---|---|---|

| Melting point | 305℃ | 270℃ |

| Maximum continuous service temperature | 260℃ | 200℃ |

| Heat resistance | A | A |

| Chemical resistance | A | A |

| Mechanical strength | B | B |

| Weatherability | A | A |

|

Non-stick Water contact angle |

115° | 114° |

|

Water vapor barrier permeability (0.1mm thickness) |

2g/m2・d | 1g/m2・d |

| Flame retardance | 94V-0 | |

| Transparency | C | A |