Chemical resistance

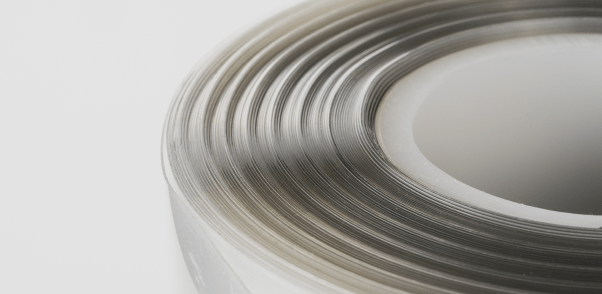

Many engineering applications components are made out of chemical resistant plastics. Not every material operate well in chemically aggressive varied environments. Amongst all resins, fluorocarbon based materials are the best plastics and elastomer solutions to enduring diverse of chemically aggressive environments. Daikin proposes a comprehensive range of solution to improve partners processing and extend parts life.

ABOUT

Why Fluoro materials are resistant to chemicals?

Fluoroplastics are composed of multiple strong carbon-fluorine bonds. This carbon-fluorine bond, called ‘C-F’ for short, is one of the strongest single bonds known. The multitude of C-F bonds in fluoropolymers gives these plastics excellent resistance to solvents, acids, and bases.

Improve processes in Chemical Plant and handling

Processing chemicals equipment and containers that withstand very aggressive and varied type of chemicals. Daikin proposes NEOFLON materials solution for valves, seals, and pumps that resist oils and aggressive fluids during any production process.

POLYFLON PTFE are also widely used in for containers or tank liners in chemical and pharma plants ensuring excellent stability and storage of the chemical processes

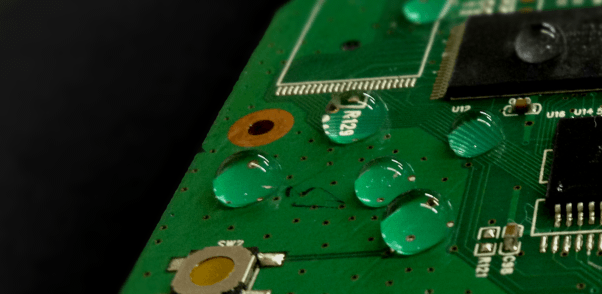

The semicon fabrication process is also relying on fluoro materials to provide the highest purity level during the handling and production to reduce default and contamination.

Chemical resistant additives and oil for increased productivity

Parts converters and film processor are continuously seeking to improve productivity by accelerating their process and reducing default. Daikin Processing Aids for compound additives and mold release agent DAIFREE used in part de-molding helps thanks to their chemical resistance to not only improve demolding but also maintain mold integrity, for longer service time.

Contribute to automotive reduction emission challenge

To meet global objectives of emission reductions the automotive industry is obliged to turbo-charged engines and function with new fuel blends. It drives hose system producer to design hoses resisting to the new and varied type of fuels at higher pressure. NEOFLON CPT for tubes and DAI-EL BRE for gasket and seal meet these stringent requirements.

Protect non-woven from alcohol and solvents

Medicals gowns, sanitary napkins, industrial operator protection are standard non-woven application requiring resistance to alcohol and solvents. UNIDYNE repellent are undisputable solution offering effective repellency and resistance to chemical resistance from oil or alcohol.

Priority from general material "D" : A+>A>B>C>D

| Product | Chemical resistance | |||||||

|---|---|---|---|---|---|---|---|---|

| Alkarine | Acid | Polar solvent | Non polar solvent | Amine | Fuel | Oil | ||

|

Fluoropolymer Fluoropolymer films Fluoro coatings Polymer additives |

PTFE | A+ | A+ | A+ | A+ | A+ | A+ | A+ |

|

PFA FEP CPT |

A | A | A | A | A | A | A | |

|

ETFE PCTFE |

A | A | A | B | B | A | A | |

| Fluoroelastomer | B | B | C | A | B | A | A | |

| Coating resins* | B | B | A | A | B | A | A | |

| Water and oil repellents | C | B | A | A | B | A | A | |

| OPTOACE confirmal coating | C | B | A | A | B | A | A | |

| Fluorinated oil | A+ | A+ | A+ | A+ | A+ | A+ | A+ | |

*measurement value of coating film blended with curing agent

The above numeric values are representative and not guaranteed.

OUR SOLUTION

APPLICATIONS

Medical industries or food and chemical processing have high expectations with regards to chemically inert materials. They demand materials that do not melt, swell, erode, or do not react even if it comes in contact with various chemicals such as alkali, acid, oxidizing agent, reducing agent, organic solvent. DAIKIN fluoro-based materials meet the most demanding challenge by offering inert materials with strong barrier properties.

- Filler neck hose

- Crank shaft seal

- Tubing / Fitting / Valve / Filter

- Sealing materials

- O-rings

- Packer seal