![]()

Under development material

08/2022

Chemical resistant coating and sealing material

Fluoro Sealant (under development)

"Fluoro Sealant", developed by Daikin, is a chemical resistant coating and sealing material, as well as an excellent water vapor barrier. A fully cured Fluoro Sealant functional film not only is an effective water vapor barrier with excellent chemical resistance, but also is capable of withstanding high voltages. Our Fluoro Sealant can be applied over a range of viscosities by a variety of techniques. Fluoro Sealant curing is initiated by exposure to moisture. It can be cured at room temperature and accelerated by heat. UV-cured formulations are additionally available. Please feel free to contact us for any questions or sample requests.

1. What is Fluoro Sealant?

Fluoro Sealant is a coating material developed by Daikin. Curing Fuoro Sealant creates a functional film with high elasticity and flexibility and can be used as a sealing or encapsulating material for protecting parts.

Compared to general silicone sealants, Fluoro Sealant shows superior resistance to chemicals and solvents, is an outstanding electrical insulator, and is more resistant to moisture permeation. Because of its high-performance attributes, Fluoro Sealant will impact various fields that have demanding applications, such as information and communications technology, automobiles, semiconductors, and medical products.

2. Features of Fluoro Sealant

(1) Chemical resistance

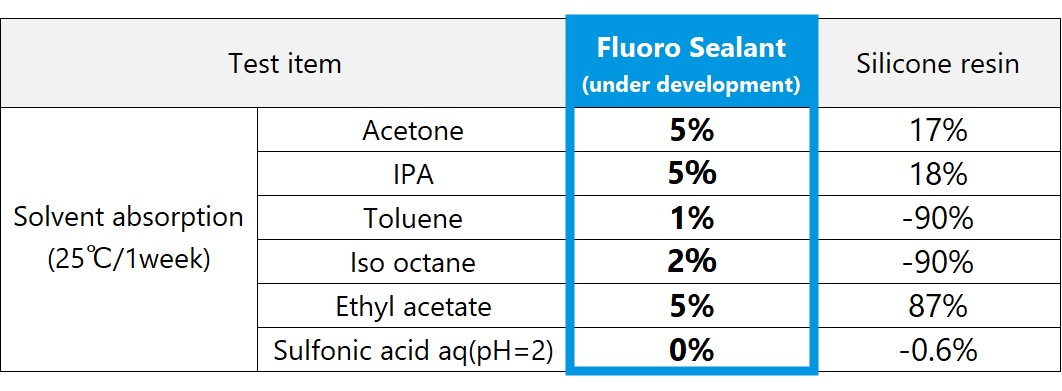

Fluoro Sealant has excellent resistance to many organic solvents and some acids. After immersion testing, a silicone resin decomposed in several test chemicals or significantly absorbed the chemicals. In contrast Fluoro Sealant showed minimal weight change, indicating that it neither significantly decomposed nor significantly absorbed chemicals.

Table.1 Solvent absorption test

Test condition

- After curing a sealant film on a glass substrate, the coated glass was submerged in each of the above chemicals for 1 week at 25℃. Then absorption rate is calculated from the film weight before and after immersion.

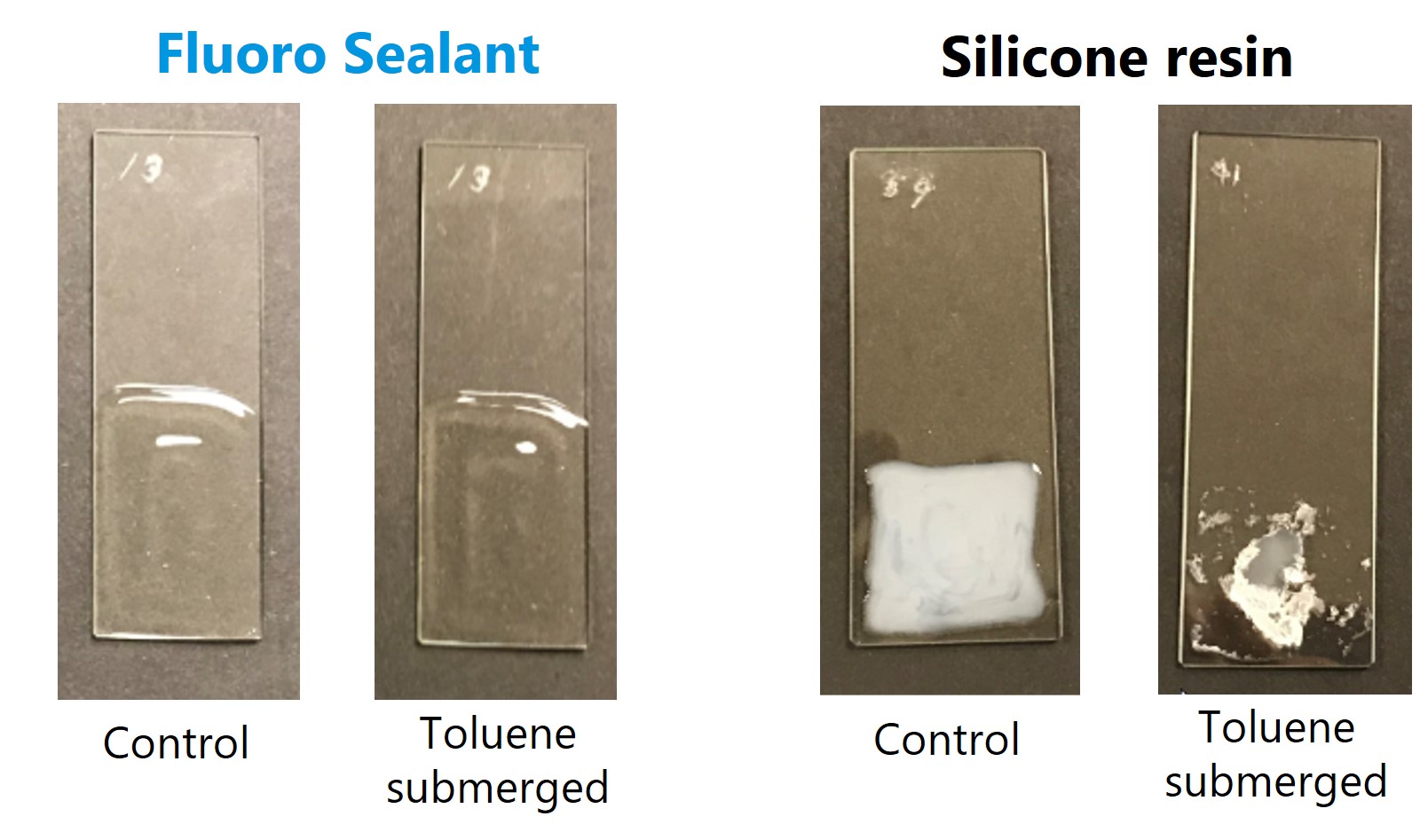

Figure.1 Before and after toluene immersion test

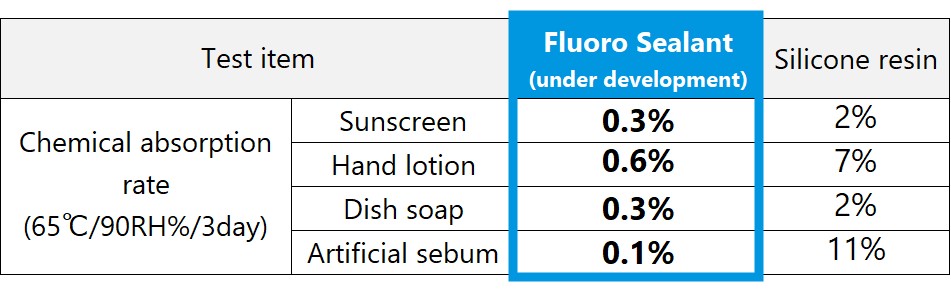

Fluoro Sealant is also resistant to daily chemicals such as oils and sunscreens, making it suitable for use as an encapsulant in wearable devices that are frequently touched by human hands.

Table.2 Swelling resistance to daily use chemicals

Test condition

- After curing a sealant film on a glass substrate, the coated glass was submerged in each of the above chemicals for 3 days at 65℃/90RH%. Then absorption rate is calculated from the film weight before and after immersion.

- Sunscreen: Neutrogena ultra sheer SPF70

- Hand lotion: Nivea cream

- Dish soap: Dawn ultra

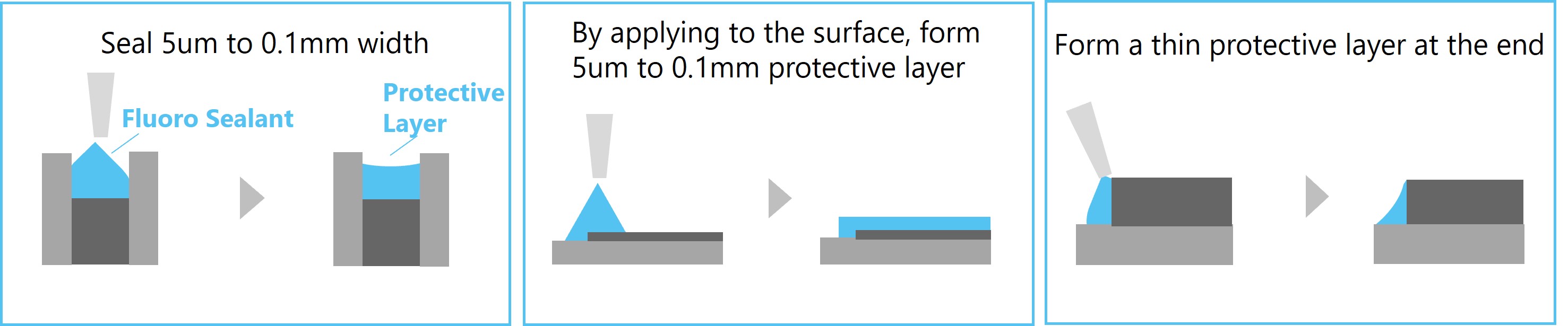

(2) Coating characteristics

Fluoro Sealant is solvent-free liquid that can be coated not only on flat surfaces, but also on a variety of shapes such as edges and gaps. In addition, since it does not contain solvents, Fluoro Sealant has a low environmental impact and does not significantly shrink due to solvent volatilization.

Figure.2 Coating methods

・Various coating methods (such as needle dispenser, jet dispenser, die coat, spin coat, etc.) may be used.

・A coating film of several microns to several millimeters can be obtained.

・It becomes tack-free in about 20 to 30 minutes at room temperature, and completely cures in a few hours to a few days.

・The curing time can be shortened by heating. We will propose coating conditions that match the purpose of use.

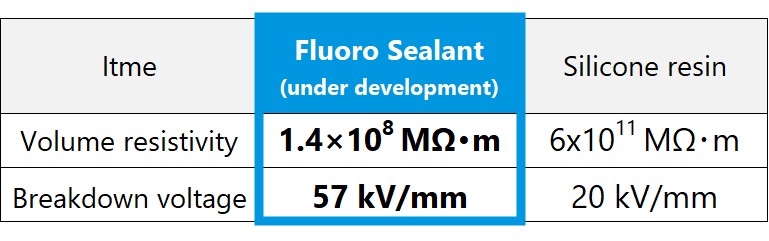

(3) Electrical insulation properties

Fluoro Sealant has a higher breakdown voltage than silicone resin and has outstanding performance as an insulating film.

Table.3 Electrical characteristics

(breakdown voltage, volume resistivity)

Test condition

- Breakdown voltage: compliant with JIS C2110-1975

- Volume resistivity: applied voltage: 10V

- Boost voltage: 10KV/16sec

- Film thickness: 0.2mm

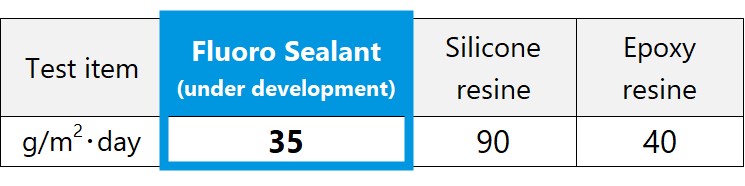

(4) Low water vapor permeability

Fluoro Sealant, even as a thin film, is excellent water vapor barrier compared to silicone resin and epoxy resin.

Table.4 Water vapor permeability

Test condition

- Cup method JIS Z 0208

- Coating thickness 30μm

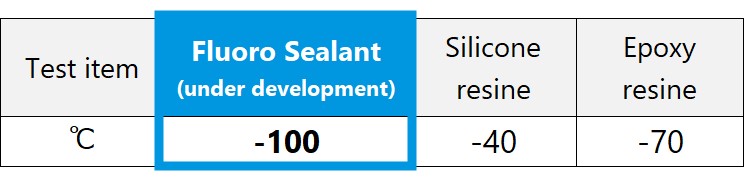

(5) Low temperature behavior

Fluoro Sealant is resistant to cold temperatures and exhibits stable elastic properties over a wide temperature range.

Table.5 Cold-resistant limit temperature

* Tg + 10 °C is defined as the cold-resistant limit temperature.

(6) Additional attributes (representative values)

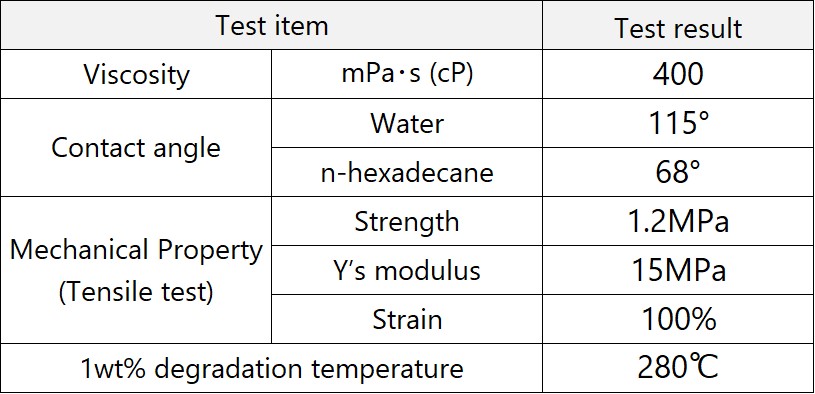

Viscosity and mechanical properties vary depending on the grade, please contact us if you have any requests.

Table.6 Additional attributes

3. Expected uses of Fluoro Sealant

As an example of application in the field of information and communications technology, Fluoro Sealant may be used as an encapsulant to fill the small gap at the edge of a display. As the wearables and designs of electronic devices become more diversified, the need to protect internal components from solvents, chemicals (cosmetics), moisture, etc. can be met by shielding them from damage with our highly chemical-resistant Fluoro Sealant.

<Other expected uses>

・Protection from automotive ATF oil

・Low temperature seal (Low temperature liquid gasket)

・Power, semiconductor, and insulating film for electrowetting

・Precision release resin

Daikin also provides technical support for the preparation of samples with different viscosities and coating methods depending on the purpose of use. Please feel free to contact us for any questions or sample requests.