MAGAZINE

Article

09/2025

Fluoro materials for future of data centers

Data centers are a vital part of today’s information infrastructure. Daikin's advanced materials promise solutions for these demands and promote the evolution of data centers.

Column

03/2025

Fluoro materials:

Catalysts for medical device evolution

Fluoro materials are renowned for their exceptionally low coefficients of friction, chemical stability, cleanliness, and biocompatibility, making them critical in a myriad of medical device applications. Daikin continues to collaborate with customers to develop new products that cater to emerging medical device needs.

Product information

02/2025

Hydrocarbon-based polymer processing aid

DAIKIN PPA DAHC-101

DAIKIN polymer processing aids (PPA) are additives that enhance productivity by reducing melt fracture and die build-up when molding polyolefin resins. DAIKIN supplies traditional PPA’s, and now hydrocarbon-based PPA’s with the launch of DAIKIN PPA DAHC-101.

Serial column

11/2024

[Battery materials] Vol.3 Dry process for lithium-ion batteries

The market trends and development movements of battery materials are featured by Takanori Suzuki, who has been engaged in the development of lithium-ion battery materials for many years and is currently a consultant for battery materials at Suzuki Material Technology and Consulting Co., Ltd. The theme of the third column of the series is “Dry process for lithium-ion batteries.”

Product information

06/2024

Fluoropolymer FEP coating powder with excellent releasability

FEP (Fluorinated Ethylene Propylene) coating powder can easily make smooth surface without pinhole. FEP film with appropriate primer helps to demonstrate strong adhesion to metal substrate and displays excellent chemical resistance and moisture resistance, thus protects metal substrate from corrosion for a long time.

Product information

10/2023

Fluorinated liquid

DAISAVE SS-54

DAISAVE SS-54 is an environment friendly fluorinated liquid with low global warming potential (GWP) and low toxicity. This fluorinated liquid is widely used in semiconductor, automotive and electronics manufacturing applications, etc.

Technical report

10/2022

Fluoromaterials attracting attention in 5G

The advent of 5G is expected to greatly improve the convenience of our communications. Daikin’s fluoromaterials and technologies are gaining attention as a way to realize and popularize the 5G concept of high-speed, high-capacity, low-latency, and simultaneous multi-connections.

Serial column

10/2022

[Battery materials] Vol.2 Binder for lithium-ion batteries

The market trends and development movements of battery materials are featured by Takanori Suzuki, who has been engaged in the development of lithium-ion battery materials for many years and is currently a consultant for battery materials at Suzuki Material Technology and Consulting Co., Ltd. The theme of the second column of the series is “Binder for lithium-ion batteries.”

Technical report

10/2022

The new opportunity of additive manufacturing with fluoropolymer PFA

Daikin has developed a fluoropolymer PFA which is suitable for additive manufacturing, powder bed fusion method (PBF method). The fluoropolymer PFA, which is excellent in chemical and heat resistance and weatherability, is expected to be developed into semiconductors, medical applications, etc.

Serial column

08/2022

[Battery materials] Vol.1 Lithium-ion batteries and fluoromaterials

The market trends and development movements of battery materials are featured by Takanori Suzuki, who has been engaged in the development of lithium-ion battery materials for many years and is currently a consultant for battery materials at Suzuki Material Technology and Consulting Co., Ltd. The theme of the first column of the series is “Lithium-ion batteries and fluoromaterials.”

Under development material

08/2022

Chemical resistant coating and sealing material

Fluoro Sealant (under development)

Fluoro Sealant is a chemical resistant coating and sealing material, as well as an excellent water vapor barrier. A fully cured Fluoro Sealant functional film not only is an effective water vapor barrier with excellent chemical resistance, but also is capable of withstanding high voltages.

Global presence

08/2022

UNIDYNE Technical Center Shanghai

The UNIDYNE Technical Center is a company based laboratory that supports technology for UNIDYNE water and oil repellents. It was established as a technical base in China, the world’s largest market for water and oil repellents used in textiles, paper, and non-woven fabrics, to accurately assess market needs and quickly respond to market needs with new product development.

Technical report

07/2022

Fluoroelastomer with different properties and its application to automotive interiors

Fluoroelastomers are increasingly expected to be applied to automotive interiors as a material that responds to changes in needs of the automotive market.

Technical report

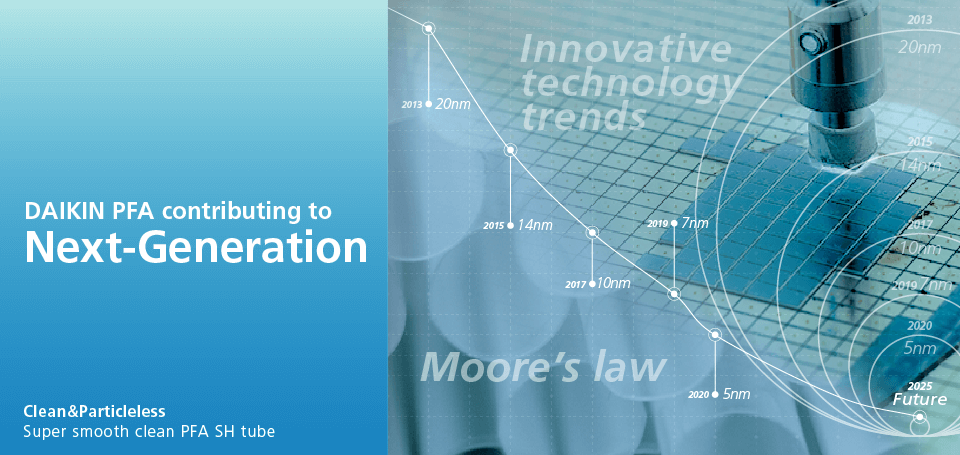

05/2022

SEMI 2021 presentation

Challenges in advanced contaminant management from materials science perspective

At the SEMI 2021 conference, Mr.Hiroyuki Hamada, Senior scientist, Product R&D development dep., Chemicals div., Daikin Industries, Ltd., gave a lecture on the challenges of advanced pollutant management in the production process of semiconductor device manufacturing equipment from the perspective of materials science.

Under development material

03/2022

Transparent piezoelectric film

(under development)

The new transparent piezoelectric film developed by Daikin features a unique property called ferroelectricity that converts force, strain, temperature change, and electrical energy in both directions. Additionally, because of its excellent transparency and flexibility, it is expected to become a key material for pressure-sensitive touch panels and wearable devices.

Webinar

03/2022

OPTOOL anti-smudge coating webinar by technical expert

OPTOOL is designed to bond to surface and can act as an anti-smudge coating mitigating the transfer of fingerprints to the modified surface.

In this webinar, Daikin technical expert is going to introduce the OPTOOL family, explain the properties, performance evaluation and application methods of OPTOOL.

Technical report

01/2022

Fluoropolymer PFA for powder bed fusion (under development)

Since high-performance materials for additive manufacturing have been developed, Daikin is developing powders for the powder bed fusion method, one of the additive manufacturing method, using fluoropolymers, a type of super engineering plastics, as raw materials. This article presents PFA powder, suitable for this method, and the physical properties of molds.

Product information

11/2021

Durable coating polymer ZEFFLE MZ for infectants and sterilants of medical devices

With the increasing demand for more infection control, the disinfectant and sterilization of medical devices is becoming more powerful, and the degradation of materials used in medical devices is becoming more serious.

To solve this problem, we offer durable coating materials ZEFFLE MZ that are resistant to various disinfectants and sterilants.

White paper

10/2021

Igniting downstream consumer demand with "Goodness of Feel" for high-touch surfaces

In this white paper, Daikin aims to describe the process by which the idea of the "Goodness of Feel" property was developed and how it can be correlated to other simple surface properties. By understanding the details of this story those familiar with hydrophobic coating technology can take advantage of this concept and utilize it to enhance the downstream value provided by their own products.

White paper

10/2021

UV-durable, water repellent coatings for automotive applications

Daikin has created a new fluorocoating, OPTOOL UD120, based on our proprietary PFPE technology with significantly increased UV resistance while maintaining water/oil repellency and abrasion resistance properties. This advanced technology is well suited for automotive applications such as camera lenses, LIDAR modules, touch displays and windows.

Technical report

09/2021

Recent progress on the measurement methodology of surface roughness inside the PFA tubes

We assume that in order to discuss the possibility of residence of nano-sized particles on the inner surface of PFA tubes for semiconductor manufacturing equipment, the method for measuring the surface roughness inside the tubes must be newly invented. This report makes a proposal for a method to measure surface roughness at the nano-level and demonstrate the necessity for this measurement.

Under development material

09/2021

Fluoropolymer / carbon fiber composite

(under development)

Daikin's new developed "Fluoropolymer / carbon fiber composite" is a type of CFRTP (Carbon Fiber Reinforced Thermo Plastic) with excellent chemical resistance.

It is also expected to be used in various applications that require structural strength, light weight, impact resistance, water and oil repellency, slidability, and heat resistance.

Under development material

08/2021 (04/2023 updated)

Automotive refrigerant (under development)

Daikin’s latest refrigerant with low environmental impacts is designed for automotive HVAC applications. It delivers increased cooling and heating capacity with superior efficiency. In particular it excels in delivering strong heating performance for an electric vehicle passenger cabin, where the exhaust heat from the combustion engine is not available, and the use of resistance heaters limits the vehicle’s range.

Interview

07/2021

Daikin San Jose Office - Silicon Valley Coating Applications Lab

Daikin prioritizes being accessible to their clients, and to bring the best possible technical assistance. Daikin’s global presence includes an open innovation facility in the heart of Silicon Valley.

Article

12/2018

Staying behind the wheel of mobility

We are entering the most exciting yet challenging era since the invention of the automotive. The entire value chain must adapt accordingly, creating synergies with their developments. Daikin’s Goal is to assist automotive engineers with their new challenges, relying upon the company’s vast interdisciplinary knowledge.

Article

12/2018

The 4 mobility trends requiring new materials

Coming from complex, multi-material moving parts in internal combustion engine (ICE) powertrains, the industry is moving towards simplified electrical powertrains with fewer parts. Daikin has worked alongside OEMs for many years and anticipated this transformation. Daikin’s agility stems from its comprehensive portfolio of solutions for the mobility industry.

Interview

07/2017

DAIKIN AUTOMOTIVE CHALLENGES

Vol.1 Chemicals in autonomous driving cars

Naoki Suganuma, an associate professor at Kanazawa University, leads the team to become the first Japanese university to conduct verification tests for autonomous driving on Japanese roads. He joins Nobuhiro Shinka, Marketing Department General Manager in the Chemicals Division at Daikin Industries, to discuss what chemical manufacturers can do in the field of autonomous driving.