![]()

Product information

02/2025

Hydrocarbon-based polymer processing aid

DAIKIN PPA DAHC-101

DAIKIN polymer processing aids (PPA) are additives that enhance productivity by reducing melt fracture and die build-up when molding polyolefin resins.

DAIKIN supplies traditional PPA’s, and now hydrocarbon-based PPA’s with the launch of DAIKIN PPA DAHC-101. DAHC-101 provides performance levels comparable to traditional aids, allowing users greater flexibility in meeting their additive needs.

1. What is PPA?

Polymer processing aids (PPA), when added to general-purpose resins, reduce melt fracture, an unintended effect that causes defects during blown and cast film extrusion. Reduction of melt fracture (MF), in turn, enhances productivity and lowers production cost.

2. What is DAIKIN PPA DAHC-101?

- DAHC-101, by reducing extrusion pressure, also enhances productivity and reduces production cost.

- DAHC-101 is a 100% hydrocarbon based polymer.

- DAHC-101 was developed as a processing aid for a broad range of for polyolefin resins, such as LLDPE, LDPE, HDPE, and PP.

- Adding DAHC-101 to polyolefin resins of 500-1,000 ppm provides a lubricious coating to the inner wall of the die, thus reducing friction between the molten polyolefin resin and the die wall, which then, minimizes melt fracture (MF) and die build-up (DBU).

3. Features

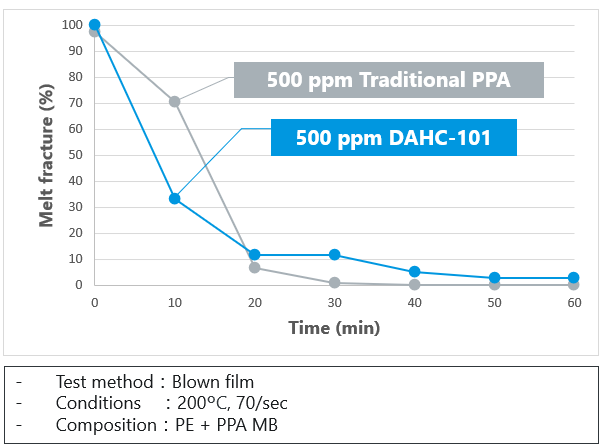

(1) Reduction of melt fracture (MF)

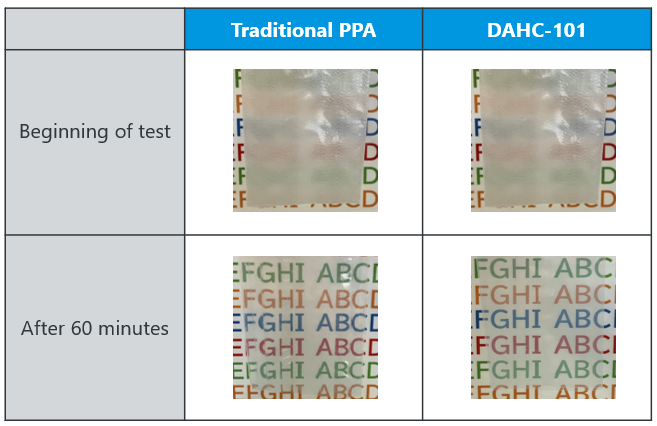

DAHC-101 reduces melt fracture (MF), enhancing the gloss and transparency of molded products.

Video1. Reduction of melt fracture with the addition of DAHC-101

In blown film molding, DAHC-101 eliminates melt fracture (MF) at the same addition level (500 ppm) of traditional PPA’s.

Figure1. Melt fracture reduction

Figure2. Film appearance

(2) Suppression of die build-up (DBU)

DBU causes deterioration to the surface quality of extruded films. Adding DAHC-101 suppresses DBU and improves extrudability.

Figure3. Appearance of die build-up (DBU)

4. Applications and resins

Applications: Blown film, cast film, pipe, tubes, wire, cable

Resins: Polyolefin resins, such as polyethylene (LLDPE, HDPE) and polypropylene

DAHC-101 complies with the following food contact regulations:

- Compliant with the U.S. Food and Drug Administration (FDA) Indirect Food Additives Regulation, 21 CFR 177.1520 under conditions of use B~H.

- Listed in Annex I of the European Commission Regulation (EU), No. 10/2011 on food contact plastic materials and articles (2011/1/14).

- Listed on the Ministry of Health (MOH), Labor and Welfare's positive list under the Japan Revised Food Sanitation Act.

Figure4. Appearance of DAHC-101

Please contact us for questions and samples.