![]()

Technical report

01/2022

Fluoropolymer PFA for powder bed fusion (under development)

Hirokazu Komori

Takayuki Matsuo

Junpei Terada

Daikin Industries, Ltd., Chemicals Division, Marketing Department

1. Introduction

Additive manufacturing has been used mainly to make prototypes and tools, but recently, with Improvement of equipment performance and high functionality of materials, as well as the cost saving and weight reduction effects by integral molding, the development of final products is progressing mainly in the fields of aircraft, automotive, and medical1). Daikin is a leading manufacturer of air conditioning equipment and fluorochemical products, and manufactures fluorochemical products such as refrigerant gases, resins, elastomers and chemicals, with over 80 years of experience in the business.

Since high-performance materials for additive manufacturing have been developed, Daikin is developing powders for the powder bed fusion method, one of the additive manufacturing method, using fluoropolymers, a type of super engineering plastics, as raw materials. This article presents PFA powder, suitable for this method, and the physical properties of molds.

2. Fluoropolymer PFA

2-1. Fluoropolymers

Fluoropolymers have high levels of heat resistance, chemical resistance, flame retardancy, weather resistance, non-adhesiveness, water and oil repellency, and various other properties due to the extremely high binding energy of the C-F bonds and low polarizability2).

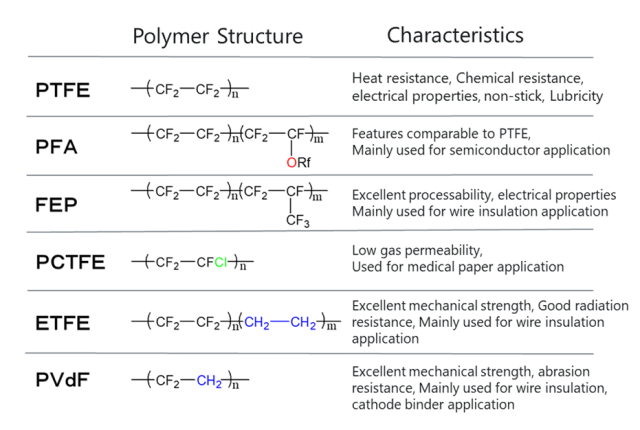

There are several types of fluoropolymers, such as PTFE (polytetrafluoroethylene). PTFE is a thermoplastic resin with excellent properties, but due to its high melt viscosity, melt molding is difficult and therefore PTFE must be processed by compressing the powder, heat-sintering and then cutting. Thus, various melt-processable fluoropolymers have been developed. Fig.1 shows some fluoropolymers that have been industrialized.

2-2. Characteristics of fluoropolymer PFA

PFA (tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer) is a melt resin which has almost the same properties as PTFE. It has excellent chemical resistance, heat resistance, flame retardancy, low relative dielectric constant, low dielectric loss tangent, non-adhesiveness and melt-processability. With these properties, PFA has a wide range of applications, including components used in semiconductor manufacturing (tubes, joints, wafer baskets, bottles, etc.), tank lining sheets, lithium-ion battery gaskets, wire insulations, and fixing rolls for OA equipment.

Fig.1 Various fluoropolymer structures

3. Powder bed fusion

3-1. Additive manufacturing technology

Beginning with the invention of photo fabrication stereolithography method by Hideo Kodama of the Nagoya Municipal Industrial Research Institute, a variety of additive manufacturing equipment has been developed and used mainly in the manufacturing industry. Today, this type of equipment is collectively referred to as "3D printing", and the range of applications has expanded to personal use including that for hobbies3).

Additive manufacturing technologies are categorized by ASTM into seven areas: (1)vat photopolymerization, (2)powder bed fusion, (3)binder jetting, (4)sheet lamination, (5)material extrusion, (6)material jetting, and (7)directed energy deposition4).

3-2. Powder bed fusion (PBF)

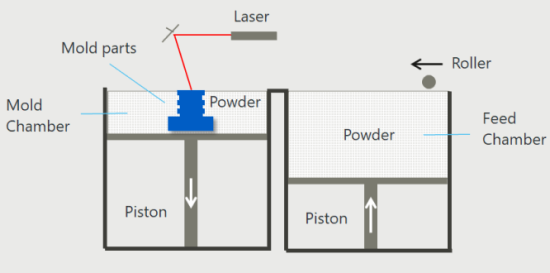

PBF is a method of forming a three-dimensional structure by spreading a thin layer of powder, selectively heating, melting and solidifying by laser and repeating this process (Fig.2). An advantage of this method is that a three-dimensional structure can be made without the supporting materials, which are needed in material extrusion and other methods4). This means the post process to remove the supporting materials is not needed. Various materials can be used for this method, including engineering plastics with high heat resistance and mechanical strength (polyamide 12, polyamide 6, PPS, etc.) and metals. For this reason, the technology is attracting the most attention as a rapid manufacturing method to fabricate final products5).

Fig.2 Schematic image of powder bed fusion (PBF)

4. Powder bed fusion using PFA

4-1. PFA powder (under development)

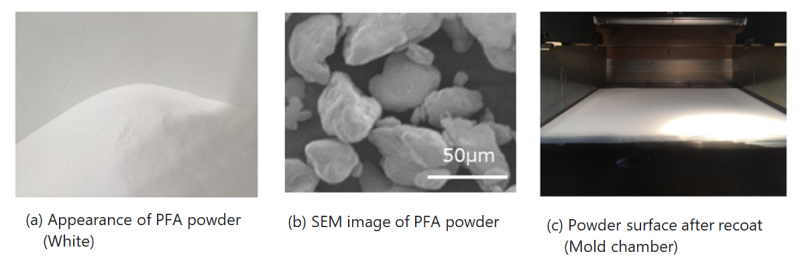

In PBF, the powder must have a high fluidity because it is supplied from the feed chamber to the mold chamber and spread (recoated) in a thin layer of 0.1 mm. The PFA powder itself we are developing shows a good recoating property without any flow improver, since we have optimized the particle size and the distribution of particle size etc (Fig.3).

Fig.3 Properties of PFA powder and recoatability

4-2. Physical properties of PFA molds

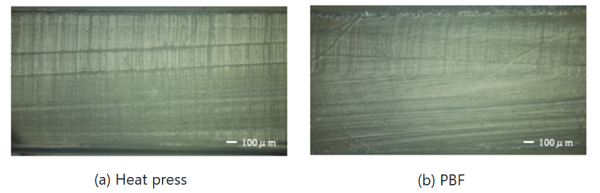

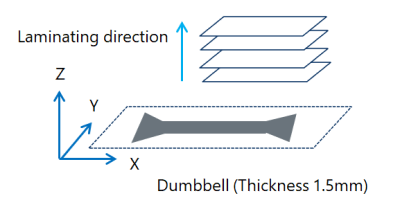

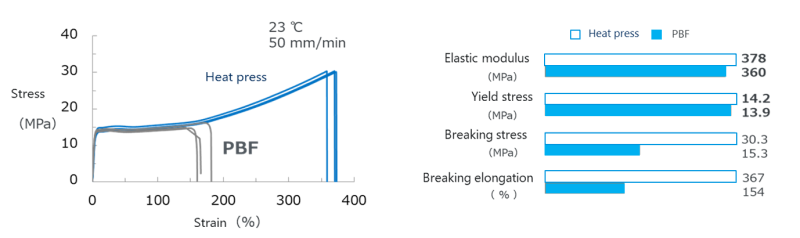

Fig.4 and Fig.5 show cross-section observation and tensile characteristics of a dumbbell molded by PBF equipment (RaFaEl II plus 300C-HT made by Aspect, Inc.) using PFA powder. A dumbbell punched out of a hot-pressed sheet is used as a reference.

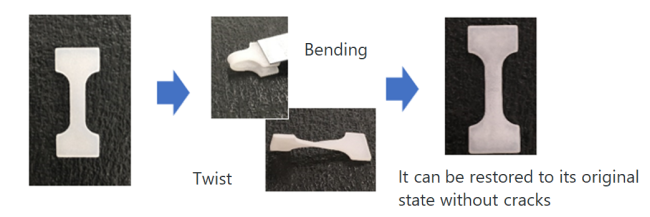

The cross-section observation shows that the dumbbell molded by PBF has no obvious voids, suggesting that the powder particles melted and bonded well each other by laser irradiation. As regards tensile properties, the elastic modulus and yield stress are the same as those of the hot-pressed sheet. Although the breaking stress and the elongation are about half those of the hot-pressed sheet, an elongation still shows about 150%. The dumbbell does not show crazing with bending and twisting, and has high toughness (Fig.6).

Fig.4 Cross section of dumbbells made by each process

Fig.5 Mechanical properties of dumbbells made by each process

(a) Laminating direction of dumbbell by PBF

(b) Mechanical properties

Fig.6 Toughness of the dumbbell made by PBF

4-3. Recyclability of PFA powder

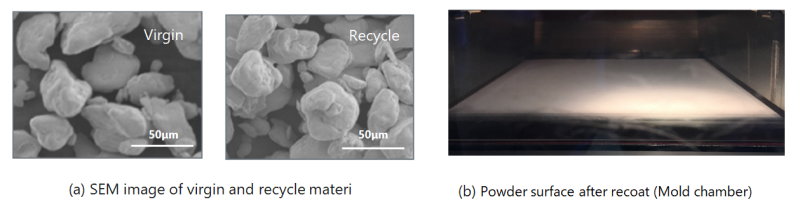

In the PBF process, powder not irradiated by laser is usually reused as recycled material. Since the material feed chamber and the mold chamber of the equipment are both preheated, it is necessary to check deterioration and degradation of the powder due to heat and determine whether it can be recycled. For this reason, we carried out a mold process using PFA powder and observed the condition of the recycled powder taken from the mold chamber using a scanning electron microscope (SEM). Then we evaluated the recoating property of 100% recycled powder and the mechanical properties of a dumbbell.

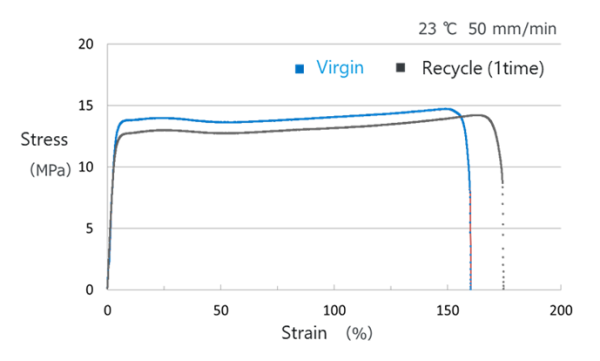

The SEM image showed no major change in particle size and shape, with good recoating property. The powder formed a uniform surface without any aggregation (Fig.7). The mechanical properties were almost the same as those of virgin product (Fig.8). Although a more detailed analysis is needed, it is presumed that there is little deterioration of the material after long exposure to high temperatures.

Fig.7 Properties of recycle PFA powder

Fig.8 Mechanical properties of recycle PFA

5. Summary

The fluoropolymer PFA has excellent chemical resistance, heat resistance and a high level toughness which are not found in other super engineering plastics. While measuring various data, we will search for applications in which molded PFA parts can be used not only in prototypes but also in end products. We would also like to work on development using fluoropolymers other than PFA and composites with other materials and presentation of optimal designs and shaping conditions using structural optimization and process simulation.

References

1) Yano Research Institute Ltd. “3D Printing Materials Market: Current Status and Future Prospects, 2016 Edition” (2017)

2) The 155th Committee on Fluorine Chemistry, Japan Society for the Promotion of Science (ed.) Introduction to Fluorine Chemistry 2010 -- Forefront of Basics and Applications, Sankyo Shuppan Co., Ltd. (2010)

3) Tsuneo Hagiwara “Latest Trends and Future Prospects for 3D Printing Materials,” Journal of the Imaging Society of Japan, Vol. 54 No. 4: 293-300 (2015)

4) Toshiki Niino “Materials for Additive Manufacturing – with Focus on Laser Sintering of Super Engineering Plastics,” Kogyo Zairyo (Engineering Materials), May 2016 (Vol. 64 No.5)

5) Seiji Hayano “Trends and Markets of AM (Additive Manufacturing) Technology," SOKEIZAI,Vol.55(2014) No.8

RELATED ARTICLES

Technical report

10/2022

The new opportunity of additive manufacturing with fluoropolymer PFA

Daikin has developed a fluoropolymer PFA which is suitable for additive manufacturing, powder bed fusion method (PBF method). The fluoropolymer PFA, which is excellent in chemical and heat resistance and weatherability, is expected to be developed into semiconductors, medical applications, etc.