![]()

Technical report

07/2023

Development of a non-fluorinated oil / grease resistant

Shun Shibata

Daikin Industries, Ltd.,

Chemicals Division

This paper was originally published in the September 2022 issue of Material Stage Journal.

1. Introduction

Daikin Industries is one of the largest fluorochemical companies in the world. UNIDYNE, a water and oil repellent, has been used in a wide variety of applications, including paper, non-woven fabrics, textiles, and carpets, since its launch in 1968 due to the combined characteristics of high water and oil resistance, and high durability. These characteristics are recognized as advantages imparted by fluorine compounds.

However, fluorine compounds have received negative attention in recent years, and there are global movements to tighten regulations. Through these movements, C8 substances were designated as persistent organic pollutants (POPs), and their use has been restricted globally. Global fluorine manufacturers began a phase-out of perfluorooctanoic acid (PFOA), also known as C8, and stated related substances. This phase-out was completed in 2015.

With the global restrictions on C8, the industry assumed that perfluorohexanoic acid (PFHXA) and related fluorine compounds (C6) could be substituted for C8. However, in recent years, the U.S. Food and Drug Administration (FDA) has raised concerns for fluorochemical impurities in food contact applications. Under these circumstances, Daikin Industries has voluntarily decided to discontinue sales of C6 oil resistant agents for paper and develop non-fluorine oil resistant agents for paper for these types of food-related applications.

Our goal was to develop an oil-resistant non-fluorine agent with the lowest surface free energy and stable performance at high temperatures that could be applied in a thin film while retaining the innate properties of paper, such as air permeability, which allows air and water vapor to pass through, and defibration, which enables recycling. Using our polymerization and blending technologies, we developed XP-8001, an oil-resistant agent for food service wrapping paper surface treatments using only non-fluorine materials.

2. Features of XP-8001

2-1. Monomer synthesis / polymer design

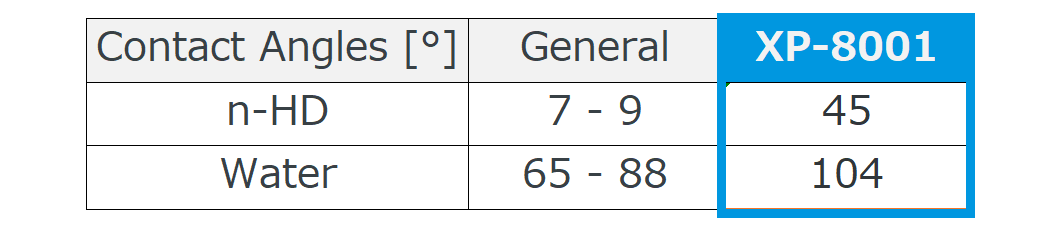

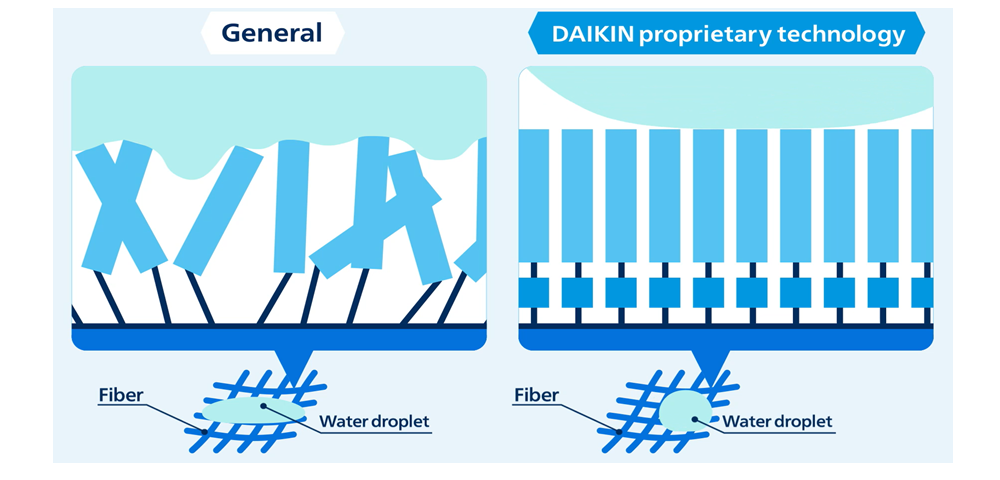

For stable oil resistance at high temperatures, CH3 ends must be placed into an ideal arrangement. Through our proprietary monomer synthesis technology, we accomplished this by constructing a molecular structure that generates an anchor at the base of the side chain that contacts the main chain. This resulted in higher contact angles compared to general-purpose technologies. Furthermore, by increasing the heat resistance of the molecular structure that generates the anchoring, stable oil resistance becomes possible even at high temperatures.

Fig.1 Contact angle comparison of XP-8001 and general-purpose technologies

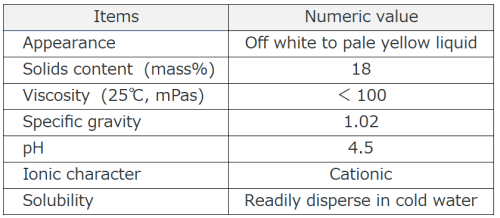

2-2. Properties

Table 1 shows the properties of XP-8001 for surface treatments, developed as a coating in order to use existing application methods such as a size press. The cationic self-dispersing oil-resistant agent was designed to promote anionic adhesion to the pulp surface. The combined use of starches is essential as a binder.

Table.1 General physical properties of XP-8001

* The above numeric values are representative and not guaranteed.

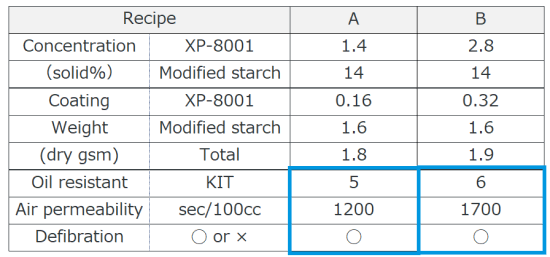

2-3. Evaluation example

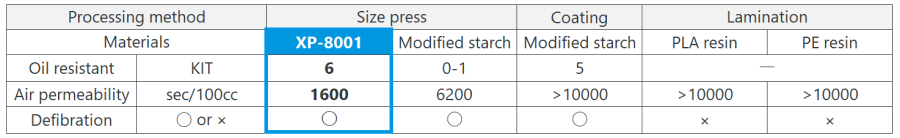

The following effect can be obtained by using XP-8001, and the evaluation effect is shown in Table 2. Combining starches makes it possible to obtain good oil resistance with a relatively thin film. Because oil resistance can be obtained even with a thin film coating, re-defibration remains possible for treated paper due to water dispersibility that retains air permeability.

Table.2 Evaluation example of XP-8001

- Treatment conditions

- - Processing method: Size press

- - Modified starch: Ethylated modified starch

- - Evaluation method: KIT (TAPPI T 559 cm-2)

- Physical properties of base paper

- - Basis weight: 48 gsm

- - Cobb 60: 45 gsm

- - Air permeability: 200 sec

2-4. Oil resistance

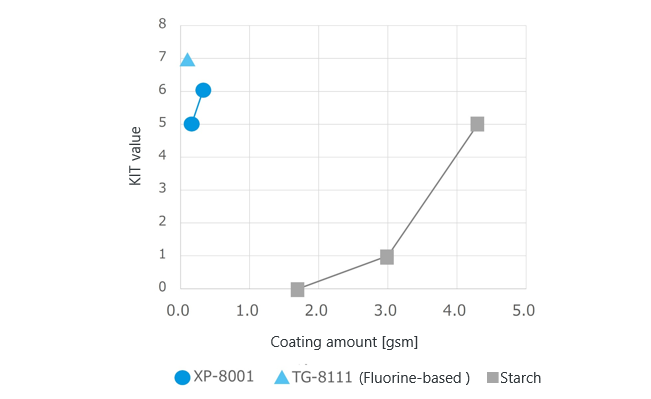

Oil resistance was evaluated by KIT: TAPPI T 559 cm-02. It is important to note that the oil-resistant agent exhibits excellent oil resistance even when the coating amount is small. XP-8001 showed high oil resistance even with a low coating amount. compared with starch-coated products, KIT: 5 was achieved with a coating amount of 1/12 or less.

Fig.2 Relation between coating amount of each oil-resistant agent and KIT value

2-5. Air permeability

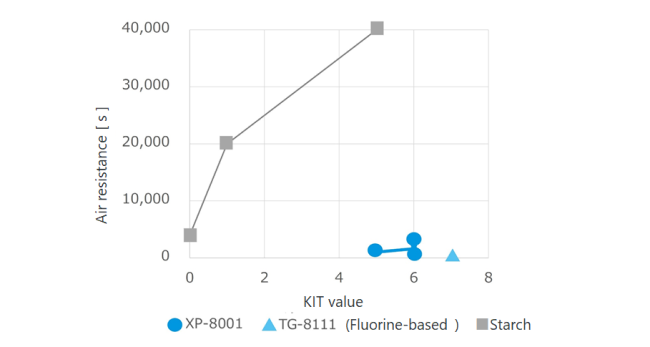

Air permeability was evaluated by the Gurley test method using air resistance as an index. Fig. 3 measures the number of seconds it takes for 100 cc of compressed air to pass through the test piece at the air resistance corresponding to KIT in Fig. 2. In general, when the coating amount of the agent is increased, gaps between the fibers become smaller and density increases, so the air permeability of the treated paper decreases. As a result, the air resistance increased in the order of TG-8111, XP-8001, and starch in proportion to the amount of coating. The air resistance of the XP-8001-coated product was about 1/25 lower than that of the starch-coated product. From this, XP-8001 was able to impart oil resistance without significantly impairing the air permeability of the base paper.

Fig.3 Relationship between KIT value and air resistance of each oil-resistant agent

2-6. Recyclabilitys

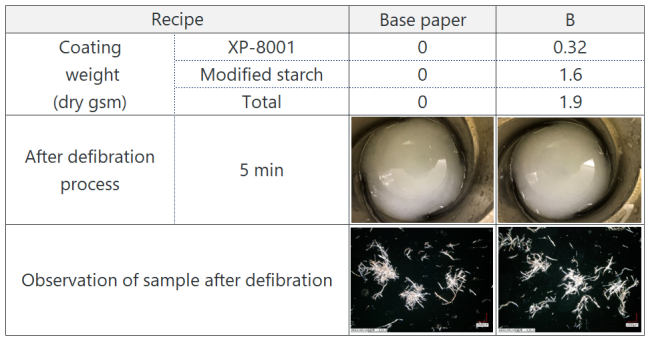

Paper can be recycled as a raw material by defibrating used paper and wastepaper. Recycling paper helps reduce deforestation. Defibration is an important element of recyclability and we evaluated whether XP-8001 inhibited the defibration. Results confirmed that paper treated with XP-8001 could be returned to pulp slurry when processed with a defibering machine. Furthermore, when the degree of dispersion of the sample after defibration was observed with a microscope, it was confirmed that the dispersion was almost the same as that of the base paper. From this fact, XP-8001 does not impede the defibration properties of the base paper, enabling even treated paper to be recycled.

Fig.4 Results of re-defibration of base paper and treated paper

3. Comparative evaluation with other existing technologies

Table 3 shows a comparison between modified starch-coated products and poly laminated paper (PLA resin and PE plastic). Modified starch-coated products tend to have high air permeability because, the coating film must be thick (2-4 gsm) to create oil resistance. On the other hand, paper with PLA and PE poly lamination fully covers fiber gaps to completely prevent water and oil penetration, but it loses air permeability. Another disadvantage occurs when recycling this type as wastepaper - it is necessary to remove the laminated resin layer. Daikin developed an oil-resistant agent that can maintain the physical properties of the base paper compared to other existing technologies.

Table.3 General physical properties of XP-8001

4. Practical evaluation

Practical evaluation of oil resistance was performed by simulating actual use methods The paper treated with XP-8001 was processed into a bag, and hashbrown potatoes heated to 80°C were placed in the bag. The degree of oil penetration was observed over time. Since oil tends to permeate the creases in folded bags, we also conducted a test in which olive oil heated to 60°C was dripped into the creases. These evaluation results are shown in Figs 5 and 6.

On the base surface where the load of hashbrown potatoes is applied, some oil seepage was observed, but almost no oil seeped into the entire bag. In addition, oil permeation around the crease portion is also suppressed. When the hashbrown potatoes were removed, the inside of the bag was not overly wet. our hypothesis is that the steam released from the hashbrown potatoes escapes through the bag. indicating the air permeability of the paper is maintained even after treatment with XP-8001.

Fig.5 Evaluation according to actual use

(Oil resistance)

*Photo taken 15 minutes after putting the hashed brown potatoes at 80°C in a bag.

Fig.6 Evaluation according to actual use

(Folded part)

*Photo taken 10 minutes after adding olive oil heated to 60°C to the crease.

5. Conclusion

We are actively developing non-fluorinated paper oil-resistant agents. We shared the excellent oil resistance of XP-8001 and the retention of the base paper physical properties. In addition to XP-8001 we are also developing oil-resistant agents for wet-end uses in the manufacture of paper plates. Going forward, we will positively contribute to the paper industry by continuing to develop products that anticipate both customer and environmental needs as we work towards a more sustainable society.

References

1) Nobuo Ishikawa, Yoshiro Kobayashi, Fluorine Compounds - Their Chemistry and Applications, Kodansha Scientific, Ltd., 1979, p. 237