DAISAVE SS-54

DAISAVE SS-54 is suitable as a cleaning agent used for cleaning electronic parts, optical parts, precision metal processing parts, etc., heat transfer media for heat pipes, dilution of fluorinated grease/oil and fluorinated coating agent, and solvent used in dry cleaning. It is a fluorine liquid.

DESCRIPTION

Features

- Zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP = 101 (AR4)).

- No flash point, providing excellent handling performance.

- Low reactivity minimizes thermal and physical impact on products, making it suitable for various substrates.

- Excellent quick-drying properties allow the solvent to easily evaporate and dry in a short time.

- Exceptional cleaning performance due to low viscosity, low surface tension, and high solubility.

- Low boiling point and can be reused by distillation.

Applications

Cleaning Solutions

【Agents for Particle Removal】

The adhesion of particles during the manufacturing of precision electronic and optical components significantly impacts product quality.

Recently, immersion ultrasonic cleaning with high-performance fluorinated cleaning agents has become widely adopted for removing adhered dust from products. These agents offer several benefits:

・Their low viscosity and small surface tension allow them to penetrate narrow gaps and effectively remove particles.

・A higher fluid density compared to water or IPA results in a greater impact force at the same flow rate, enhancing cleaning performance.

・A wide range of ultrasonic frequencies can be chosen, minimizing damage to products and enabling single-agent cleaning.

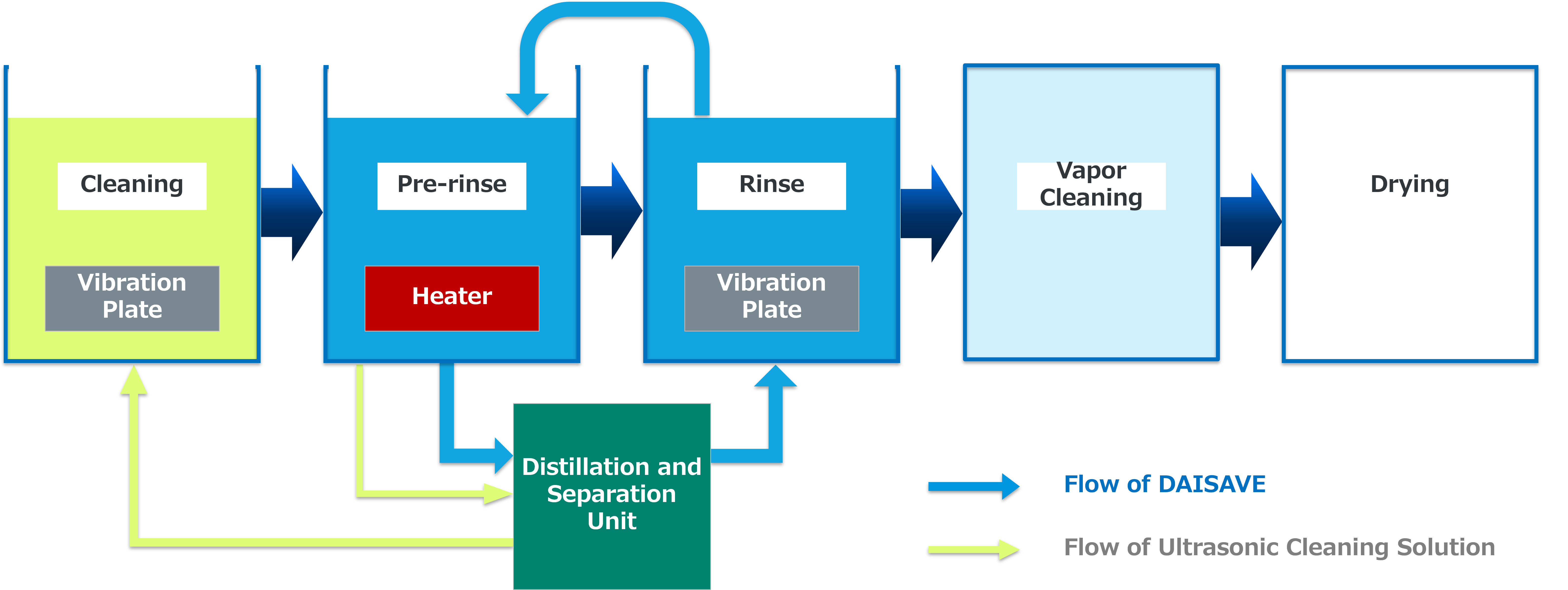

【Agents for Rinse Cleaning】

In the rinse cleaning process, which replaces water droplets adhered to the product surface, a method using fluorinated agents for cleaning and drying has been established to reduce drying time, improve quality, and lower equipment costs.

These agents are particularly effective for cleaning parts with fine holes, narrow gaps, or those that cannot be cleaned at high temperatures. Benefits include:

・Excellent quick-drying properties that allow for uniform drying, preventing water spots, improving drying yield, and shortening drying time.

・Low-temperature drying, which reduces thermal impact on products compared to hot-air drying.

・Low reactivity, reducing physical impact on products and allowing for the cleaning of a wide range of materials.

Solvent Solutions

【Dilution of Fluorinated Contact Grease & Coatings】

Fluorinated coatings are extensively used for electronic components, precision parts, and optical components ddue to their superior properties, including:

・Moisture-proof

・Oil-resistant

・Anti-fouling ・Corrosion-resistant ・Dust-proof ・Chemical-resistant properties

Fluorinated solvents are safe to handle and ideal to dilute and form very thin film coatings on metals, glass, and resins, making them ideal for diluting fluorinated coatings.

Key advantages include:

・Small Surface Tension: Allows for the stable application of thin films, making them suitable for precision coatings.

・No Flash Point: Eliminating the need for explosion-proof measures for coating and ventilation equipment, as well as electrical equipment like lighting.

・Excellent Quick-Drying Properties: Shortens the time required for film formation, minimizing visual impact and enhancing efficiency.

Solvent for Dry Cleaning

In dry cleaning, it is crucial to effectively remove stains while preserving the texture of the fabric and preventing chemical burns from cleaning odors or solvent residues.

Fluorinated solvents are preferred for their easy handling and efficiency, offering several key benefits:

・No Flash Point: Provides excellent handling performance and fewer restrictions on installation locations.

・Distillable and Reusable: Fluorinated solvents can be frequently distilled and reused, maintaining a fresh state, reducing cleaning odors.

・Gentle on Fabrics: Exhibits low reactivity with fabrics, resulting in a soft, flexible finish.

Fluorinated Liquid DAISAVE SS-54

TECHNICAL DATA

Physical Properties

| Item Category | Item | SS-54 |

|---|---|---|

| Operating Temperature Range | Boiling Point [°C] | 54 |

| Freezing Point [°C] | -92 | |

| Electrical Properties | Volume Resistivity [Ω・cm] | 109 |

| Dielectric Constant | 8.9 | |

| Thermal Properties | Kinematic Viscosity [cSt] 25°C | 0.40 |

| Thermal Conductivity [W/m・k] 25°C | 0.081 | |

| Specific Heat [kJ/(kg・K)] 25°C | 1.31 | |

| Density [g/cm³] 25°C | 1.39 | |

| GWP | 101 | |

Applicable Substrates

| Resins | ABS, AS, Epoxy Glass, PA6, PA66, PBT, PC, PE, PET, PF, POM, PP, PPE, PPS, PS, PVC, PTFE, FEP, PFA |

|---|---|

| Rubber | Chloroprene Rubber, Chlorosulfonated Polyethylene Rubber, Nitrile Rubber, EPDM, Butyl Rubber, Natural Rubber |

| Metals | Magnesium, Aluminum, Titanium, Iron, Nickel, Copper, Zinc, Molybdenum, Silver, Tin, Tantalum, Tungsten, Lead, Brass, SUS304, SUS316 |