- HEAT RESISTANCE / OIL RESISTANCE

- 耐熱性 / 耐油性

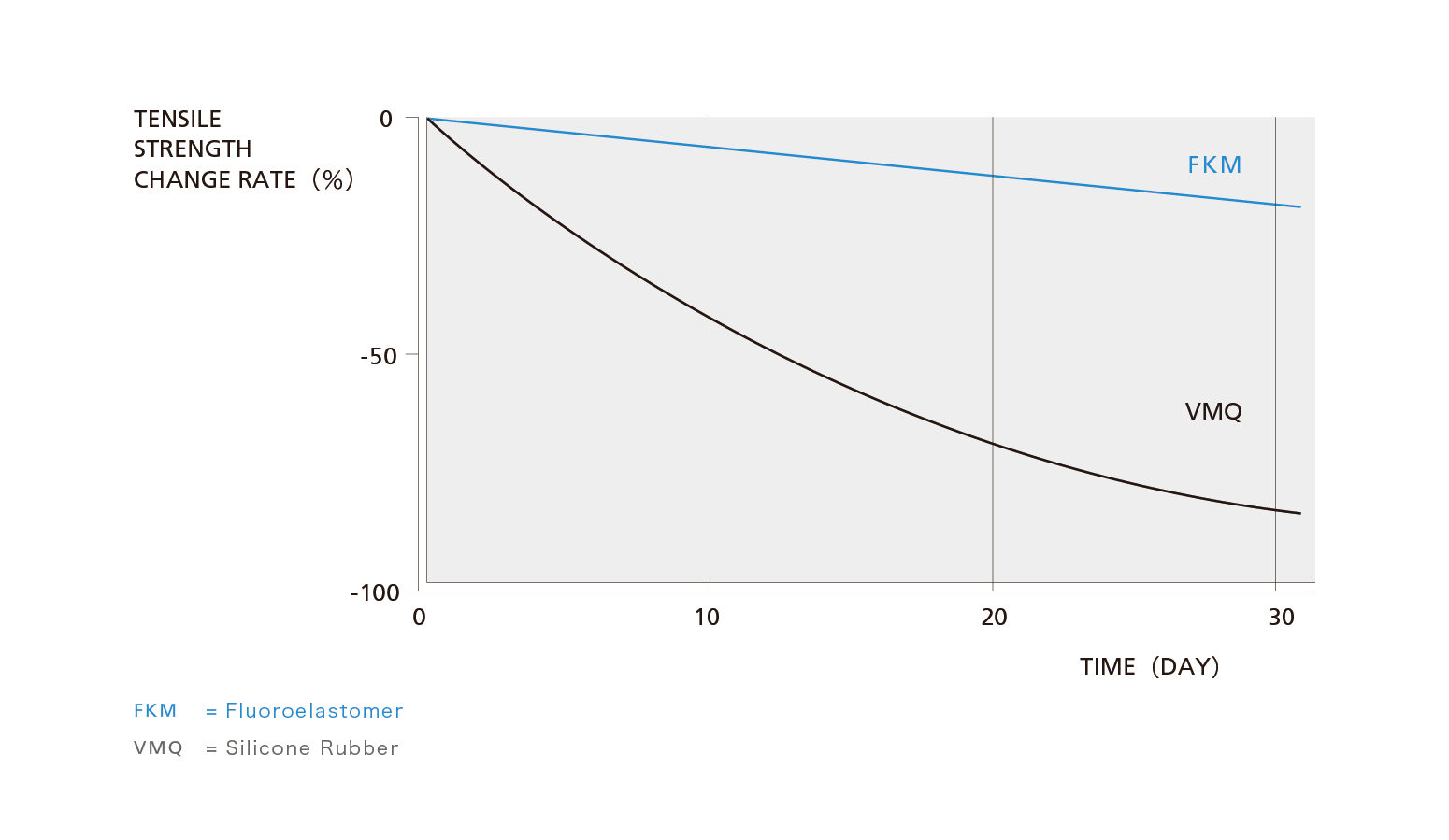

Fluoroelastomers (FKM) can be used in rubber materials even under harsh conditions that reach temperatures of 230° C and are an elastomer that provides the best balance of heat and oil resistance. With fluorine atoms, heat and oil resistance improves due to high binding energy and low cohesive energy between molecules.